Why Digital Printed Pouches Are Hurting New Food Brands

| 15 Jan 2026

Why Digital Printed

Pouches Are Hurting New Food Brands

A Cost, Margin &

Packaging Strategy Guide for Food Startups

In the current food startup ecosystem, founders are

often seduced by the allure of "premium" aesthetics. When you hold a

digitally printed sample, it looks vibrant, requires no cylinder investment,

and feels ready for a boutique shelf.

However, there is a dangerous disconnect between Design

Appeal and Unit Economics.

The hard truth rarely told by design agencies is

this: Digital printed pouches often destroy gross margins, choke working

capital, and complicate supply chains for emerging brands.

This guide dissects the financial and operational

reality of packaging, offering a roadmap for entrepreneurs who want to build a

sustainable business, not just a pretty product.

The "Premium

Trap": Why Founders Get Confused

Most early-stage food founders enter the market

with three anxieties:

- How do I differentiate my brand?

- How do I avoid the high upfront cost of rotogravure

cylinders?

- How do I launch quickly with low Minimum Order

Quantities (MOQs)?

Digital printing appears to be the magic bullet. It

offers low MOQs (sometimes as low as 500 pieces) and high-definition graphics.

The Invisible Downside:

While you save on upfront cylinder costs, you pay a

massive premium on the per-pouch cost.

- Packaging is not marketing art; it is a cost system.

- Every rupee spent on a pouch is a rupee taken

directly from your profit margin.

- If your packaging cost is 15-20% of your selling

price, you will struggle to offer retailer margins or survive price wars.

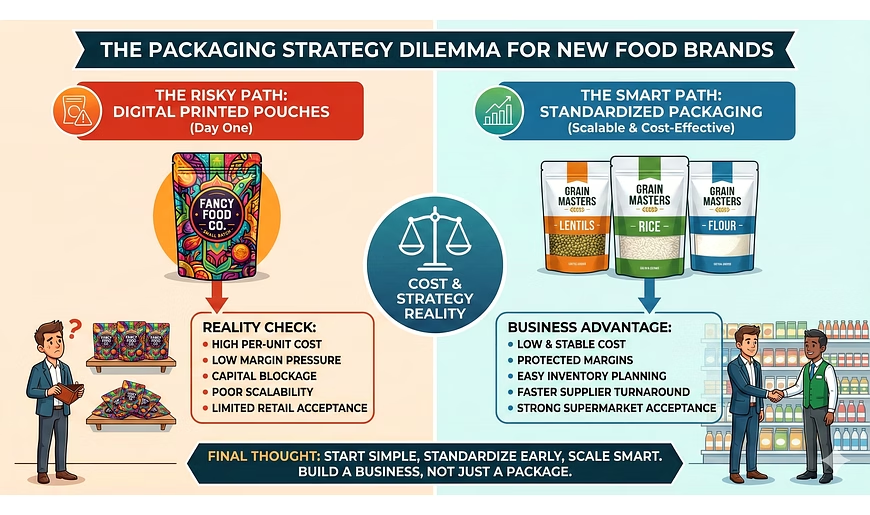

The Tale of Two

Strategies

New brands generally fall into one of two

categories. History shows that only one of these paths leads to scalable

success.

❌ Practice 1: The

"Digital First" Approach (High Risk)

- The Strategy: The brand chooses digital printing immediately to

avoid cylinder costs and print complex, multi-color designs for every SKU.

- The Consequence:

- Unit Economics: The cost per pouch is significantly higher (often

3x-4x) than standard printing.

- Scale trap: As volumes grow, digital prices do not drop

drastically. You remain stuck with high packaging costs while competitors

lower theirs.

- Inventory Complexity: You cannot easily change variable data (like

MRP or dates) without re-printing.

✅ Practice 2: The

Standardized "Master Shell" Approach (Recommended)

- The Strategy: Used by margin-conscious brands (and giants like

Tata Sampann or private labels). They use a Common Laminate Structure

and a Base Design.

- The Execution:

- The "Master" design (Brand logo,

background pattern) is printed in bulk.

- Differentiation (Product Name, Variant, Barcode) is

achieved via color-coding or minimal cylinder changes.

- Pro Tip: Some ultra-lean startups use a high-quality plain

pouch with a premium, machine-applied label until they hit critical

volume.

- The Advantage:

- Drastically lower cost per pouch.

- Faster supplier turnaround.

- Retailers trust the format (it looks like a serious

FMCG product, not a boutique experiment).

🔍 Cost & Strategy

Comparison: The Reality Check

The following table breaks down why standardized

packaging wins on business fundamentals.

|

Factor |

Standardized Packaging (Rotogravure/Flexo) |

Digital Printed Pouches |

|

Cost Per Pouch |

Low & Stable (High margin protection) |

High (Eats into gross profit) |

|

MOQ Scalability |

Easy (Cost drops as volume rises) |

Restricted (Cost stays relatively high) |

|

Capital Efficiency |

Excellent (Money is in product, not plastic) |

Poor (High OpEx spend) |

|

Barrier Properties |

High Reliability (Proven shelf life) |

Variable (Depends heavily on digital ink/substrate) |

|

Retail Perception |

High (Looks like a mass-market leader) |

Limited (Perceived as niche/expensive) |

Strategic Insight: Retailers prioritize supply consistency and

shelf velocity. A standardized pack suggests you have the backend to

restock quickly. A hyper-customized digital pouch suggests you are a small

batch producer who might run out of stock.

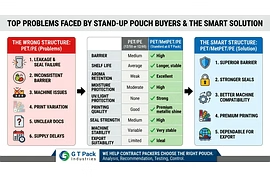

Product Deep Dive:

Flexible Packaging Specifications

To make the right choice, you must stop thinking

like a designer and start thinking like a manufacturer. Below are the technical

specifications that balance cost, protection, and retail acceptance.

1. Recommended Material Structures

You do not need exotic materials. You need proven

barriers against moisture, oxygen, and light.

|

Structure Code |

Layers |

Ideal Application |

Why It Works |

|

PET / PE |

Polyethylene Terephthalate + Polyethylene |

Pulses, Grains, Atta (Flour), Sugar |

Excellent strength, clear printing,

cost-effective. |

|

PET / MET-PET / PE |

Added Metallized Layer |

Spices, Masalas, Tea, Coffee |

The Gold Standard. The middle metal layer blocks light and retains

aroma. |

|

BOPP / CPP |

Biaxially Oriented Polypropylene + Cast PP |

Dry Snacks, Biscuits, Pasta |

High clarity, moisture barrier, gives a

"crinkle" feel. |

|

PET / ALU / PE |

Added Aluminum Foil |

Premium Exports, Ultra-sensitive Powders |

Maximum barrier (total light/oxygen block). |

2. Standardized Size

Guide

Using standard sizes allows you to buy generic

outer cartons and ensures your product fits on standard retail shelves. Avoid

custom dimensions.

Category : Grains & Pulses

·

500g : 160mm x 250mm

·

1kg : 180mm x 300mm

·

5kg : 300mm x 450mm

Category : Spices & Masala’s

·

50g : 90mm x 140mm

·

100g : 120mm x 180mm

·

200g : 140mm x 220mm

·

500g : 160mm x 250mm

Category : Flour / Atta

·

1kg : 200mm x 300mm

·

5kg : 350mm x 550mm

3. Pouch Formats

- Center Seal / Pillow Pouch: Lowest cost. Best for laying flat or hanging

strips. (Chips, small spices).

- Stand-Up Pouch : Premium shelf presence. Stands vertically.

Good for muesli, snacks, or premium grains.

- Side Gusset: Best for bulk items (1kg+ rice/flour) as it creates

a block shape for stacking.

🚀 The Smarter Way to

Launch

If you are a startup with limited budget, do not

jump straight to digital. Follow this "Packaging Graduation"

path:

- Phase 1 (The MVP): Use stock plain pouches (silver, white, or kraft) +

High-quality, professionally designed stickers. This keeps inventory

flexible and costs rock bottom.

- Phase 2 (The Hybrid): Once you have 2-3 hero products, move to a Standardized

Rotogravure Pouch (Common design) and print flavor variants.

- Phase 3 (The Scale Up): Full dedicated cylinders for each SKU only

when volumes exceed 100,000 units per run.

Final Verdict: Packaging

is a Business System

Digital printed pouches are not inherently

"wrong"—they are a tool. But they are often the wrong tool for the

early growth stage.

To survive the retail shelf:

- Standardize early.

- Prioritize barrier quality over print novelty.

- Scale your packaging only when your sales volume

justifies it.

This discipline is what separates a "brand experiment" from a scalable FMCG business.

people use these with other names - digital printing vs rotogravure cost, why is digital packaging expensive, packaging cost reduction strategies, packaging mistakes food startups make, reduce packaging cost per unit, cost effective food packaging, packaging margin analysis, high cost of digital printed pouches, food packaging for low margins, rotogravure cylinder cost ROI, food startup packaging guide, packaging for small food business, low MOQ packaging India, best packaging for new food brands, private label food packaging, packaging strategy for FMCG, how to scale food business packaging, startup friendly packaging solutions, standardized packaging vs custom, launch food brand on budget, flexible packaging pouches, stand up pouches for food, center seal pouch manufacturer, side gusset pouches for grains, food grade laminate structures, PET poly pouch specifications, moisture barrier packaging, spice packaging pouch material, flour packaging bags wholesale, dry fruit packaging pouches, met pet pouch advantages, standard pouch sizes for food, digital printed stand up pouches, digital flexible packaging, custom printed pouches no minimum, short run flexible packaging, digital print food labels, digital pouch printing pros and cons, no cylinder packaging printing, food packaging, custom packaging, flexible packaging, pouch design, packaging solutions, retail packaging, packaging suppliers, printed pouches, wholesale packaging, packaging design trends, shelf life packaging