Center Seal vs Side Seal vs Gusset vs Stand-Up Pouches: Which Packaging Is Right for Your Product?

| 20 Dec 2025

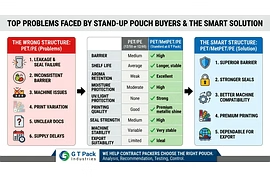

Choosing the right flexible packaging pouch is not a design

decision—it’s a business decision. The pouch you select affects product

safety, shelf life, logistics cost, machine efficiency, customer perception,

and profitability.

Yet many food brands, FMCG manufacturers, and exporters

choose pouch types based on trends or supplier suggestions—leading to leakage,

excess cost, or poor shelf performance.

In this guide, we break down the difference between

Center Seal Pouches, Side Seal Pouches, Gusset Pouches, and Stand-Up Pouches,

explaining when to use each, what products they suit best, and how to choose

the most cost-effective option for your business.

This guide helps you clearly understand when to use which

pouch, so your packaging supports your business instead of limiting it.

Quick

Comparison Table

|

Criteria |

Center

Seal Pouch |

Side

Seal Pouch |

Gusset

Pouch |

Stand-Up

Pouch |

|

Primary

Use Case |

High-volume, cost-sensitive products |

Leak-prone powders & liquids |

Bulk & high-fill products |

Retail-facing, premium products |

|

Seal

Structure |

Single back (center) seal |

Dual side seals |

Side or bottom gussets + seals |

Bottom gusset + side seals |

|

Material

Consumption |

Lowest |

Low–Medium |

Medium |

Highest |

|

Barrier

Customization |

Excellent |

Excellent |

Excellent |

Excellent |

|

Machine

Speed Compatibility |

⭐⭐⭐⭐⭐ |

⭐⭐⭐⭐ |

⭐⭐⭐ |

⭐⭐⭐ |

|

Export

Suitability |

Yes |

Yes |

Yes |

Yes |

|

Branding

Space |

Moderate |

Moderate |

Large |

Maximum |

|

Best

For |

Snacks, spices, sugar, salt |

Liquids, powders, chemicals |

Rice, pet food, coffee beans |

Snacks, dry fruits, FMCG retail |

Why Pouch Selection Matters More Than You Think?

Packaging failures don’t always show up immediately. They appear later as:

- Moisture

damage

- Leakage

during transit

- Product

spoilage

- Customer

complaints

- Higher

logistics costs

- Weak

shelf presence

The correct pouch format, combined with the right laminate

structure, prevents these problems before they happen.

All Pouch

Types at a Glance

|

Pouch

Type |

Best

For |

Cost

Efficiency |

Shelf

Presence |

Leak

Resistance |

Bulk

Handling |

|

Center

Seal Pouch |

High-volume, cost-sensitive products |

⭐⭐⭐⭐⭐ |

⭐⭐ |

⭐⭐⭐ |

⭐⭐⭐ |

|

Side

Seal Pouch |

Liquids & fine powders |

⭐⭐⭐⭐ |

⭐⭐ |

⭐⭐⭐⭐⭐ |

⭐⭐⭐ |

|

Gusset

Pouch |

Bulk & heavy products |

⭐⭐⭐ |

⭐⭐⭐ |

⭐⭐⭐⭐ |

⭐⭐⭐⭐⭐ |

|

Stand-Up

Pouch |

Retail & premium products |

⭐⭐ |

⭐⭐⭐⭐⭐ |

⭐⭐⭐ |

⭐⭐⭐ |

1. Center Seal Pouches – Best for High-Volume & Cost Control

Center Seal Pouches (also called back seal pouches) are the most commonly used packaging format in mass-market food and FMCG industries.

When to Choose Center Seal Pouches

- You

pack large volumes (lakhs or crores of units)

- Cost

per pouch directly impacts margins

- Product

is dry or low-leak risk

- Shelf

display is not the main priority

Common Products

- Snacks

& namkeen

- Spices

& masalas

- Sugar,

salt, pulses

- FMCG

commodity packs

Why They’re Popular

- Lowest

material consumption

- Fastest

machine speeds

- Highly

economical for scaling

If your priority is low packaging cost with reliable protection, center seal pouches are usually the smartest choice.

2. Side Seal Pouches – Best for Liquids & Leak-Sensitive Products

Side Seal Pouches are sealed on both sides, creating stronger seams that can handle pressure, fine powders, and liquids.

When to Choose Side Seal Pouches

- Product

is liquid, paste, or fine powder

- Leakage

cannot be tolerated

- Export

or long transit is involved

- Seal

strength is more important than shelf display

Common Products

- Sauces

& liquid foods

- Protein

& nutritional powders

- Chemicals

& granules

- Institutional

food packs

Key Advantage

Side seal pouches offer the highest leak resistance

among flat pouch formats.

If buyers search “best pouch for liquid packaging” or

“leak-proof packaging pouch,” side seal pouches are the correct solution.

3. Gusset Pouches – Best for Bulk & Heavy Products

Gusset Pouches include side or bottom gussets that expand when filled, allowing higher capacity and better weight distribution.

When to Choose Gusset Pouches

- Pack

sizes are medium to large (250g–10kg)

- Product

weight stresses flat pouches

- You

want flexible packaging instead of rigid bags

- Stacking

and storage efficiency matters

Common Products

- Rice,

grains & pulses

- Pet

food

- Coffee

beans

- Bulk

snacks & dry foods

Why Brands Choose Gusset Pouches

- Handles

heavy fill weights safely

- Better

carton utilization

- Lower

freight cost than rigid packaging

Gusset pouches are ideal for searches like bulk food packaging pouch or heavy-duty flexible packaging.

4. Stand-Up Pouches – Best for Retail & Premium Branding

Stand-Up Pouches (Doypacks) feature a bottom gusset that allows the pouch to stand upright on shelves.

When to Choose Stand-Up Pouches

- Shelf

presence drives sales

- Product

is consumer-facing

- Branding

and design matter

- Resealability

is required

Common Products

- Snacks

& dry fruits

- Coffee

& tea

- Retail

spices

- Health

foods & supplements

Why They Convert Better

- Maximum

shelf visibility

- Premium

look and feel

- Higher

perceived product value

Stand-up pouches use more material and cost more than center seal pouches — but often justify it through higher retail pricing.

How to Choose the Right Pouch (Simple Decision Guide)

- Lowest

cost, highest volume → Center Seal Pouch

- Leakage

risk is critical → Side Seal Pouch

- Heavy

or bulk products → Gusset Pouch

- Retail

branding & visibility → Stand-Up Pouch

Many successful brands use multiple pouch types

across different SKUs instead of forcing one format everywhere.

Pouch Type Alone Is Not Enough – Structure Matters

No pouch works without the right laminate structure.

Performance depends on:

- Foil

vs non-foil layers

- Micron

thickness

- Inner

sealing layer

- Product

behavior (oil, moisture, pressure)

At G T Pack Industries, pouch selection always starts

with product analysis, not just format selection.

Why Buy Pouches from G T Pack Industries?

- In-house

lamination, printing, slitting & pouching

- 6

& 8-color rotogravure printing

- Solvent

lamination for strong bonds

- Structures

designed for Indian & export climates

- Technical

guidance—not just selling rolls

Frequently Asked Questions (FAQ): Flexible Packaging

Pouch Selection

1. Which pouch type is best for food packaging?

There is no single “best” pouch for all food products. The

right pouch depends on product type, shelf-life requirement, moisture

sensitivity, packaging volume, and budget.

- Dry,

high-volume foods → Center Seal Pouch

- Liquids

or fine powders → Side Seal Pouch

- Bulk

or heavy products → Gusset Pouch

- Retail,

branded products → Stand-Up Pouch

Choosing based on application—not appearance—prevents

spoilage and unnecessary cost.

2. What is the difference between center seal and

stand-up pouches?

The main difference is cost and shelf presence.

- Center

Seal Pouches are more economical, use less material, and run faster on

machines.

- Stand-Up

Pouches consume more material but offer better shelf visibility and

premium appearance.

Brands often use center seal for economy SKUs and stand-up

pouches for premium retail packs.

3. Which pouch is best for liquids and sauces?

Side Seal Pouches are the safest option for liquids, sauces,

oils, and semi-liquid products.

Their dual side seams provide higher seal strength and

pressure resistance, reducing leakage during transport and storage—especially

important for exports and long-distance distribution.

4. Are gusset pouches suitable for heavy products?

Yes. Gusset Pouches are specifically designed for medium to

heavy fill weights.

Side or bottom gussets expand when filled, distributing

weight evenly and reducing stress on seals. They are commonly used for:

- Rice

and grains

- Pet

food

- Coffee

beans

- Bulk

snacks

They are a flexible alternative to rigid bags or boxes.

5. Which pouch type gives the longest shelf life?

Shelf life depends more on the laminate structure than the

pouch shape.

For maximum shelf life:

- Use

foil-based laminates (PET / Aluminium Foil / PE)

- Ensure

proper micron thickness

- Match

sealing layer to product behavior

Any pouch type—center seal, side seal, gusset, or

stand-up—can deliver long shelf life if engineered correctly.

6. Is stand-up pouch packaging more expensive?

Yes, stand-up pouches are generally more expensive than

center seal pouches because:

- They

use more material

- Bottom

gussets add complexity

- Often

include zip locks

However, many brands justify the cost through higher MRP,

better retail conversion, and stronger branding.

7. Can one brand use multiple pouch types?

Absolutely—and most successful brands do.

For example:

- Economy

SKU → Center Seal

- Premium

retail SKU → Stand-Up

- Bulk

pack → Gusset

- Liquid

SKU → Side Seal

This strategy optimizes cost, performance, and shelf

presence across the product range.

8. Are all pouch types suitable for export packaging?

Yes, all pouch formats can be export-ready when:

- Correct

laminate structure is used

- Seal

strength is validated

- Barrier

is designed for climate variation and transit duration

Export failures usually happen due to wrong structure

selection, not pouch type.

9. What laminate structure should I choose: foil or

non-foil?

- Foil

laminates → Best for aroma-sensitive and long shelf-life products (spices,

coffee, nutraceuticals)

- Non-foil

laminates → Suitable for fast-moving products and cost-optimized SKUs

The choice depends on shelf-life target, storage conditions,

and budget.

10. Which pouch runs fastest on packaging machines?

Center Seal Pouches generally offer the highest machine

speed and efficiency, followed by side seal pouches.

Stand-up and gusset pouches may require speed optimization

depending on:

- Size

- Thickness

- Zippers

or valves

11. Does pouch type affect packaging cost significantly?

Yes. Pouch selection directly impacts:

- Material

consumption

- Production

speed

- Wastage

- Logistics

cost

Choosing a pouch that is over-engineered for your product

often increases cost without adding real value.

12. Can I reduce packaging cost without changing pouch

type?

Yes. Cost optimization can be done by:

- Adjusting

laminate thickness

- Switching

foil to non-foil (where feasible)

- Optimizing

pouch dimensions

- Improving

sealing layer efficiency

Format change is not always required.

13. Which pouch is best for humid climates like India?

In humid environments:

- Moisture

barrier is critical

- Foil

or high-barrier structures are recommended

All pouch types can work in humidity if the laminate

structure is selected correctly.

14. How do I choose the right pouch for a new product

launch?

Start with these four questions:

- Is

the product dry, oily, liquid, or powder?

- What

shelf life is required?

- Will

it be sold retail or bulk?

- What

is the target price point?

Once these are clear, pouch type and structure selection

becomes straightforward.

15. Who should help me decide the pouch type—designer or

manufacturer?

Always consult a packaging manufacturer or packaging

engineer, not just a designer.

Designers focus on appearance. Manufacturers focus on:

- Performance

- Shelf

life

- Machine

compatibility

- Cost

control

The best results come when design follows structure, not the

other way around.

Final Thoughts: Choose Smart, Not Trendy

Packaging should support your product, protect your

margins, and strengthen your brand. There is no “one best pouch”—only the right

pouch for the right product.

Right pouch + right laminate = stable product +

controlled cost + happy customers.

If you’re unsure, choosing incorrectly costs far more than

asking an expert.

Need Help Selecting the Right Pouch?

📩 Contact G T Pack

Industries for:

- Product-based

pouch recommendations

- Structure

comparison samples

- Cost

vs performance analysis

- Export-ready

packaging guidance

Right packaging reduces complaints, improves margins, and

builds trust.