Food Packaging Reality Check: What Every New Food Business Must Understand Before Choosing Packaging

| 17 Dec 2025

Food Packaging Reality Check: What Every New Food Business Must Understand Before Choosing Packaging

Starting a food business is exciting. Recipes are perfected, branding ideas are flowing, and distribution plans are taking shape.

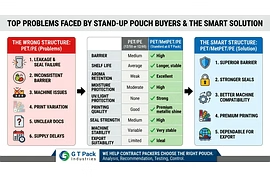

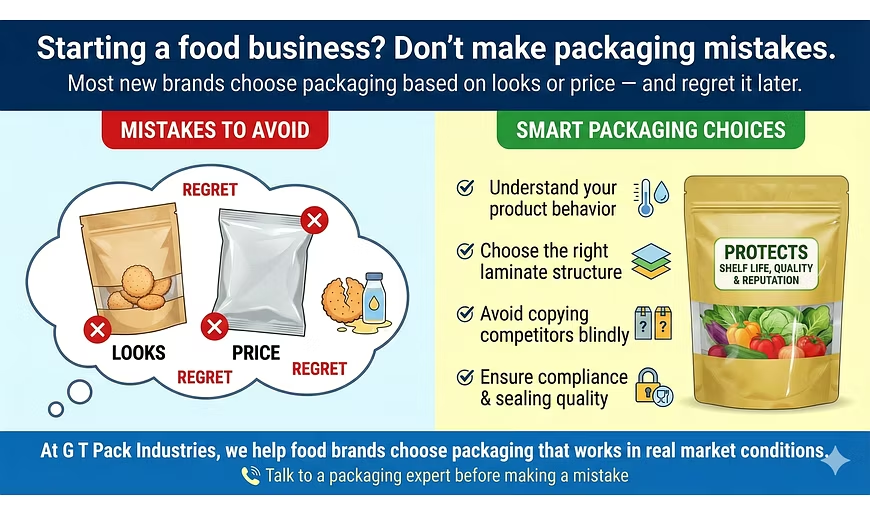

But one critical area where most new food entrepreneurs make costly mistakes is packaging.

As a packaging manufacturer working closely with food brands across India, one hard truth stands out:

Most newcomers approach packaging in the wrong direction.

- They look for shortcuts.

- They copy competitors.

- They chase the lowest price.

And later, they pay for it with spoilage, leakage, customer complaints, and rebranding costs.

This blog is written to save you from those mistakes.1. Packaging Is Not a Pouch – It Is Product Protection

Packaging is often misunderstood as just a printed pouch or bag.

In reality, packaging is a technical system designed to protect your product from:

-

Moisture

-

Oxygen

-

Aroma loss

-

Oil migration

-

Contamination

-

Physical damage during transport

Your packaging decides:

-

Shelf life

-

Product consistency

-

Brand trust

-

Repeat purchases

If packaging fails, no marketing can save your product.2. The First Question You Must Answer (Before Calling Any Manufacturer)

Before contacting a packaging supplier, you must clearly understand your product.

Ask yourself:

-

Is my product dry, oily, or hygroscopic?

-

Is it sensitive to moisture or oxygen?

-

Does aroma retention matter?

-

What shelf life am I targeting?

-

How will the product be stored and transported?

Packaging is always decided by product behavior, not by design preference.3. Common Packaging Myths That Mislead New Brands

Let’s break some dangerous myths:

Myth: Thicker packaging means better quality

Reality: Wrong structure with higher thickness still fails

Myth: Aluminium foil is best for everything

Reality: Overuse increases cost and sometimes causes sealing issues

Myth: Copying competitor packaging is safe

Reality: You don’t know their product formulation or storage conditions

Myth: Cheapest rate saves money

Reality: Poor packaging leads to higher long-term losses

Smart packaging is about right material, not expensive material.4. Understanding Packaging Structure (In Simple Language)

Most food packaging uses multi-layer laminates, where each layer has a role:

-

Outer layer: Printing & branding (PET / BOPP / Paper)

-

Middle layer: Barrier protection (Met PET / Aluminium / EVOH)

-

Inner layer: Food contact & sealing (LDPE / LLDPE / CPP)

Each layer must be chosen based on product needs, not assumptions.

One laminate does not fit all products.5. Choosing the Right Pouch Type (Looks vs Logic)

Different pouch styles serve different purposes:

-

Center Seal Pouch : Cost-effective, high-volume products

-

Stand-Up Pouch : Better shelf visibility and branding

-

Side Gusset Pouch : Higher strength, bulk products

-

Pillow Pouch : Vertical filling machines

-

Vacuum / MAP Packs : Extended shelf life

Choose pouch style based on:

-

Filling method

-

Distribution channel

-

Storage conditions

Not just shelf appeal.

6. Printing & Design: Where New Brands Overspend

Printing makes your product visible — but it does not increase shelf life.

Common mistakes:

-

Too many colors increasing cylinder cost

-

Design without regulatory text

-

Poor readability

-

Ignoring brand consistency

Good packaging design is clear, compliant, and functional.7. Compliance Is Not Optional

Every food pack must comply with basic regulations:

-

FSSAI license number

-

Net quantity

-

Ingredient list

-

Allergen declaration

-

Manufacturing & expiry details

-

Veg / Non-veg symbol

Ignoring compliance can block your product at distributor or retailer level.

8. MOQ & Pricing Reality of Packaging Manufacturing

Packaging is not a retail product; it is manufactured.

Costs include:

-

Raw materials

-

Printing

-

Lamination

-

Cylinder

-

Pouch making

-

Wastage & setup loss

Low MOQs are limited due to machine setup economics.

Understanding this saves frustration on both sides.

9. How to Approach a Packaging Manufacturer Correctly

Before sending an inquiry, prepare:

-

Product details

-

Monthly requirement

-

Target market

-

Filling method

-

Shelf-life expectation

Ask for solutions, not just rates.Final Advice from a Packaging Manufacturer

A good packaging partner does more than sell material.

He helps you avoid mistakes that could damage your product and brand.

Packaging done right once is cheaper than fixing it later.