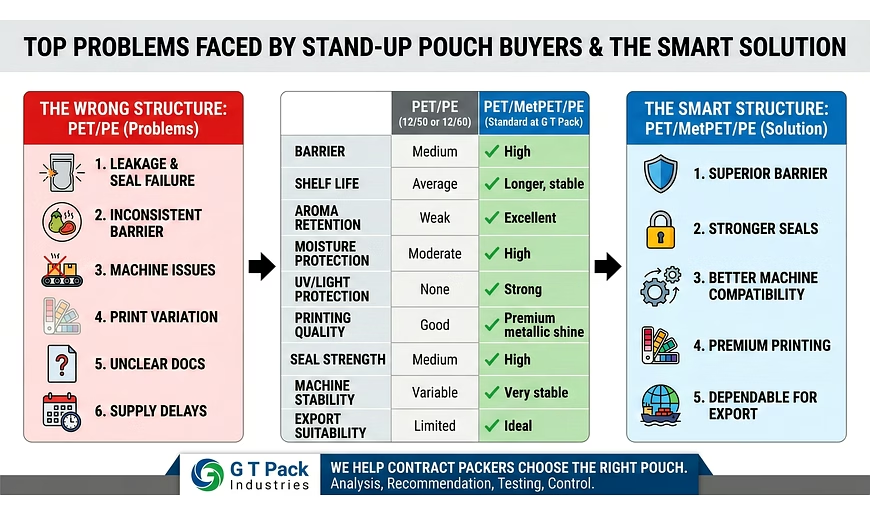

Top Problems Faced by Stand-Up Pouch Buyers

| 09 Dec 2025

Top

Problems Faced by Stand-Up Pouch Buyers — And Why PET/MetPET/PE Is the Smartest

Standard Structure for Contract Packers

Stand-up pouches have become the preferred

packaging format for food, FMCG, spices, dry fruits, coffee, pet food, home

care, and export items. They look premium, offer better shelf

visibility, reduce logistics cost, and support faster filling—but

they also bring hidden challenges that many contract packers and brand

owners struggle with.

From leakage issues to printing defects,

from poor barrier performance to machine compatibility problems,

the wrong laminate structure can disrupt operations and increase

rejection rates dramatically.

At G T Pack Industries, we work closely with

contract packers, manufacturers, and exporters who depend on stable,

predictable, and high-barrier packaging. Over the years, we have studied

hundreds of pouch failures and found one common truth:

Most problems in stand-up pouches come from using the wrong structure — especially low-barrier PET/PE combinations.

That is why we have standardized PET/MetPET/PE as our recommended structure for the majority of food and FMCG applications. It solves the top pain points faced by contract packers while offering strong visual appeal and dependable performance on high-speed machines.

# Top

Problems Faced by Stand-Up Pouch Buyers

1. Leakage, Seal Failure & Weak Sealing Layer

- Poor seal layers, inconsistent PE thickness, or

incorrect sealing windows cause:

- Corner leaks

- Zipper leaks

- Powder leakage during export

- Coffee/dry fruit aroma loss

- Complaints from retail buyers

- A single batch with seal failure can damage a

brand’s trust.

2. Inconsistent Barrier Performance

- Most buyers underestimate moisture and oxygen

sensitivity in:

- Dry fruits, Spices, Coffee, Namkeen, Masala mixes,

Frozen items

- Low-barrier PET/PE structures allow oxygen and

moisture to penetrate—reducing shelf life, crispness, and aroma

retention.

3. Machine Compatibility Issues

- If the pouch laminate is too soft, too stiff, or the

seal layer is incompatible with the filling line:

- The line slows down

- Seals do not form properly

- Gussets don’t open cleanly

- Pouches fall on conveyors

- Rejection rates increase

- This is a direct operational loss for contract

packers.

4. Print Variation & Colour Problems

- PET/PE lacks metallic base support, causing:

- Dull colours

- Washed-out branding

- Visible imperfections

- Weak product shelf impact

- When brands compete on colour and premium feel, this

is unacceptable.

5. Unclear Food Safety Documentation

- Many small converters fail to provide proper

documents such as:

- Food-grade certificates

- Migration test reports

- Laminate specifications

- Batch traceability

- This slows down audits for exporters and large FMCG

buyers.

6. Supply Delays & Unpredictable Lead Times

- Stand-up pouches require multiple production stages.

When converters outsource printing or lamination, delays become

frequent.

- This disrupts contract packing schedules that run on

tight timelines.

# Why G

T Pack Industries Recommends PET/MetPET/PE as the Standard Structure

PET/MetPET/PE is

widely considered the most reliable and performance-driven laminate

for premium stand-up pouches. Here’s why:

1. Superior Barrier Protection

- The MetPET layer provides:

- High oxygen barrier

- High moisture barrier

- UV/light protection

- Aroma retention

- Shelf life stability

2. Stronger, Cleaner Seal Formation

- The PE layer bonds beautifully with heat seal jaws,

giving:

- Zero leakage

- Consistent seals

- High burst strength

- Excellent tolerance on high-speed lines

3. Better Machine Compatibility

- PET + MetPET combination offers stiffness and

body, which helps pouches:

- Stand properly

- Run smoothly on filling lines

- Maintain shape in logistics

- Work well on zipper and non-zipper formats

4. Premium Printing Quality

- The metallic base enhances colours dramatically:

- Higher gloss

- Better opacity

- Sharper colours

- More premium branding

5. Dependable for Both Domestic & Export

Conditions

- MetPET performs better under:

- High temperature

- High humidity

- Long-distance logistics

- Container storage

# PET/PE vs PET/MetPET/PE — Practical Comparison

|

Feature |

PET/PE (12/50 or

12/60) |

PET/MetPET/PE

(Standard at G T Pack) |

|

Barrier |

Medium |

High |

|

Shelf Life |

Average |

Longer, stable |

|

Aroma Retention |

Weak |

Excellent |

|

Moisture Protection |

Moderate |

High |

|

UV/Light Protection |

None |

Strong |

|

Printing Quality |

Good |

Premium metallic shine |

|

Seal Strength |

Medium |

High |

|

Machine Stability |

Variable |

Very stable |

|

Export Suitability |

Limited |

Ideal |

|

Cost |

Lower |

Mid-range (value-for-performance) |

# How

We Help Contract Packers Choose the Right Pouch

- Competitor pouch analysis

- Product-specific laminate recommendation

- Pouch samples for machine testing

- In-house manufacturing control

# Before You Order Pouches, Ask Yourself This:

- What problem am I really trying to solve?

- Barrier? Aroma? Seal strength? Print quality?

Machine speed?